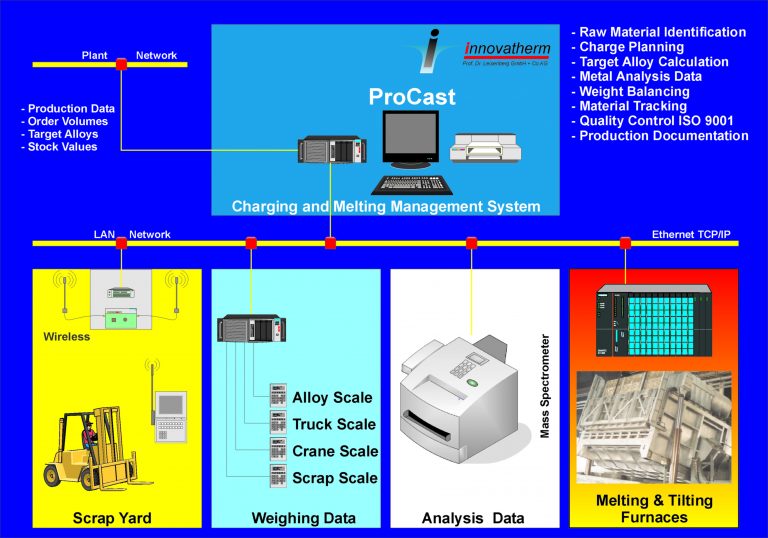

ProCast Charging and Melting Management System

innovatherm provides the ProCast Charging and Melting Management System to optimize the production in primary or secondary Casthouses. It is based on fuzzy logics and advanced generic algorithms providing functions for an optimized charging and melting procedure at lowest raw material costs and best economics.

The charging management is integrated into a complete automated solution, starting at charge assignment, including charge calculation and charge tracking.

The ProCast System is providing the following functions:

- Scrap and raw material identification at Scrap Yard

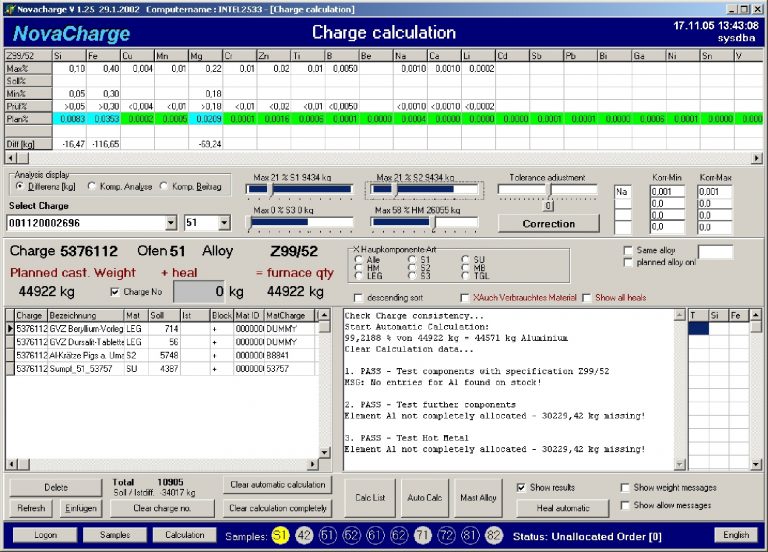

- Charge planning for each batch and each furnace

- Automatic Target Alloy Calculation and Optimisation of Batch Costs

- Supervision of Metal Analysis

- Weight Balancing for each Furnace

- Material Tracking through the Casthouse

- Quality Control according to ISO 9001

- Production Documentation

ProCast iteratively calculates the best and most economic batch for the desired target alloy, taking into account the current metal analysis and the lowest material input costs.

The current prices can optionally be queried via an on-line connection. Additionally, a material flow tracking system for the complete foundry can be implemented based on a WiFi radio network.

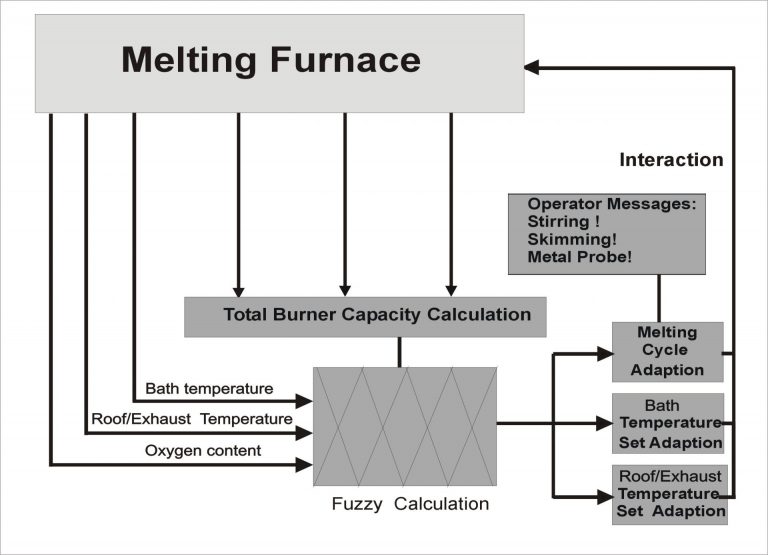

The Melting Module – Melting optimization for foundries and Casthouses

The Melting management, as an additional module to ProCast, optimizes the melting process at the furnace systems with regard to the target sizes:

- Reduction of melting times, improvements of > 8% are achievable,

- Reduction of dross formation, improvements of > 12 % can be achieved,

- Reduction of energy consumption, improvements of > 10 % can be achieved, and

- Increase of product quality and

- Reduction of specific CO2 emissions.

For this purpose, the Melting Module processes the current temperature values, energy input and the status of the current charging and melting cycles. From these values, the necessary target values for bath and roof temperatures and production cycles are calculated on the basis of fuzzy control algorithms.