ProBake Firing System

innovatherm Firing and Control System ProBake combines 40-years of experience in open top and closed type anode baking furnaces with the latest firing and control technology, incorporating the latest measurement, diagnosis and control technologies.

ProBake offers the best approach for an efficient and economical operation on

- existing or new furnace design

- fuel oil or natural gas fired systems

ProBake achieves the following goals:

- high and consistent anode quality

- complete tar burn

- complete volatile combustion

- lowest energy consumption,

- lowered NOx and CO emissions

innovatherm designs, supplies and commissions complete firing systems for anode baking furnaces with the following features and additional components:

Process engineering

- Turn-key installations, for fully automatic safe operation of the furnace,

- all necessary safety and alarm interlocks,

- fire change in less than 20 minutes and

- preparation of the entire equipment for a change of firing direction.

- easy adaptation to different furnace designs,

- easy operation and maintenance,

- automatic “cross-over” strategy (firing around the corner),

- safety package for low draft situations,

- gas safety test with dynamic monitoring,

- automatic zero adjustment of all pressure sensors (cyclic).

Mechanics

- Cooling ramps, controlled, with central or individual fans,

- Zero point ramps for zero pressure control,

- Burner ramps for gas or oil with Ultra Low NOx burner and extremely low maintenance dosing valve with 500.000.000 switching cycles,

- Measuring ramps for draft control,

- Exhaust ramps with automatic draught/temperature control

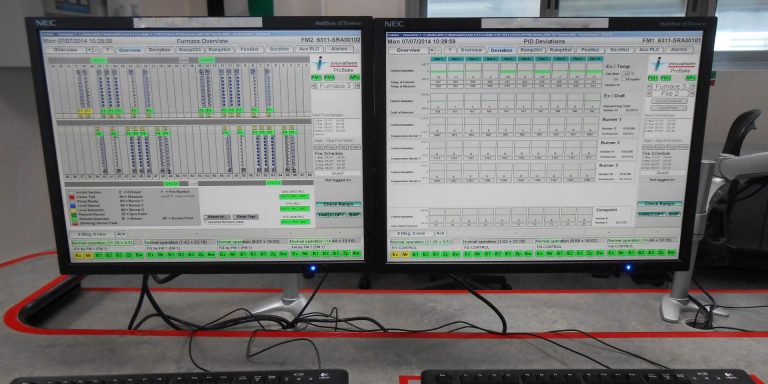

Automation Technology

- Transparent system architecture,

- Standardized PLC and PC hardware,

- Windows 10 or Windows Server operating system,

- Highest availability and reliability,

- Robust plugs for safe plugging,

- Multiple redundancy, hot stand-by,

- Long-term data archiving by means of ProDat software,

- Easy connection to PPS systems via Ethernet TCP/IP,

- Wireless radio network TCP/IP Wireless with 54Mbit/sec

- Software

The following modules are provided for the optimization of the firing process

- Flooding Index Module,

- Firing Index Module,

- Pitch burn Module,

- Flue Condition Module.

- Flow Control Module

Technological Advantages of the System

The ProBake System provides the following advantages:

- Lowest energy consumption, low as down to < 1,7 GJ/t

- Pitch burn module for maximum pitch volatile combustion

- Flow Control Module, Flow Prediction for each flue by Fuzzy Logics

- Highest Firing Flexibility by section oriented baking curves

- Wi-Fi Technology (Wireless) for high reliability and low maintenance

- Low NOx Burner Technology for lowest emissions

- Innovatherm Short Pulse Dosing Valve, 500.000.000 switching cycles guaranteed

- RFID Technology for Automatic Position Detection

- Long Life Flue Thermocouple Type S with patented shock adsorber technology

The integration of special customer requirements and experience into the firing system is a matter of course. Scaled solutions can be implemented as well.

The ProBake firing system from innovatherm represents the optimum solution tailored to the customer’s needs with future-oriented equipment.